Organic Compostable Fuel Cells: Powering IoT with Sugar

The global IoT boom—projected to reach 27 billion connected devices by 2024 (per Gartner)—has a hidden environmental cost: billions of disposable lithium-ion batteries, most of which end up in landfills, leaching heavy metals like lead and cobalt into soil. For an industry striving for sustainability, and for those who rely on IoT tech in agriculture, urban management, or smart homes, this waste loop has long been a paradox. Enter organic compostable fuel cells: a breakthrough that uses sugar—one of the most abundant, low-cost organic compounds—to power IoT devices, while breaking down into nutrient-rich soil after use. This innovation isn’t just eco-friendly; it’s redefining how we think about long-term, low-maintenance power for small-scale electronics.

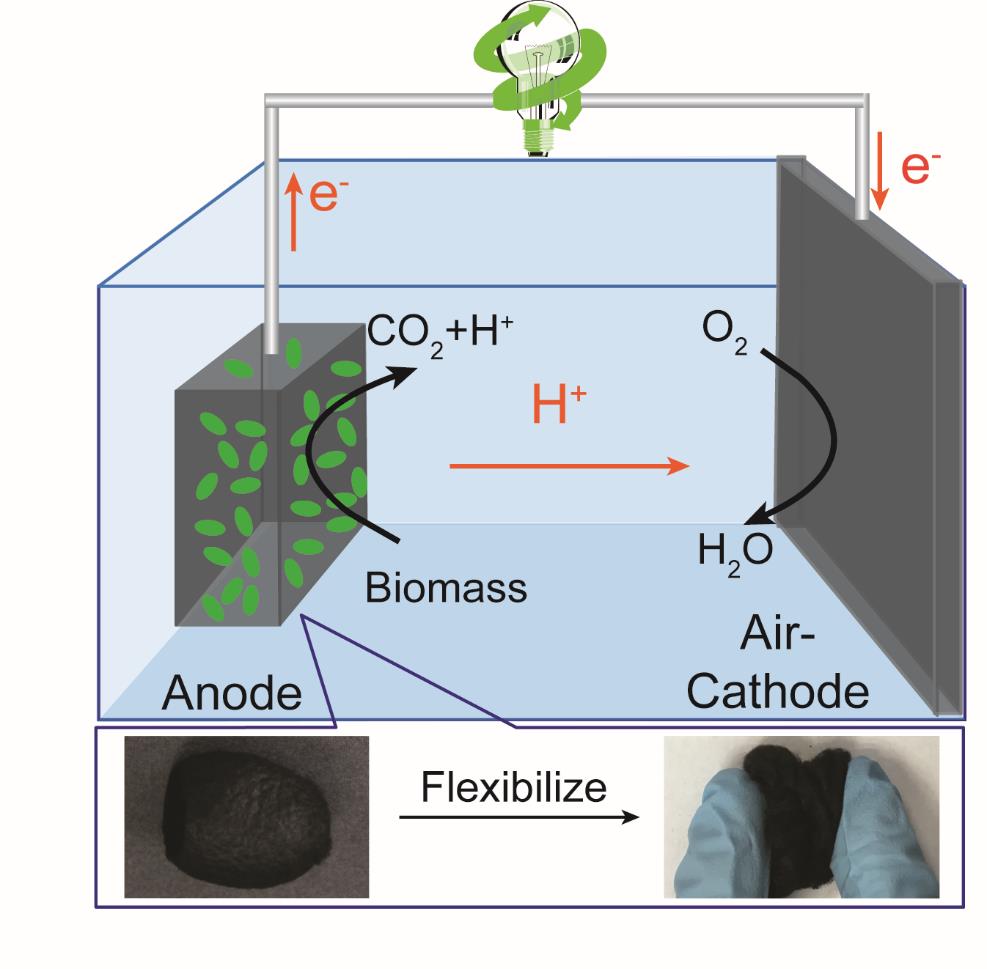

At the core of these fuel cells is bioelectrocatalysis, a process that mimics how living organisms convert sugar into energy. Unlike traditional batteries, which store energy chemically, these cells use enzymes (like glucose oxidase) to break down glucose molecules from sugar—whether from table sugar, fruit juice, or plant waste—into electrons, protons, and carbon dioxide. The electrons flow through a circuit to power low-energy IoT microchips, while protons combine with oxygen to form water. Crucially, every component—from the solid-state electrodes (made from corn starch and chitosan) to the electrolyte solution (a biodegradable gel)—is compostable. After the sugar is depleted (typically 3–6 months of use), the entire cell decomposes in soil within 90 days, leaving no toxic residue—a stark contrast to lithium-ion batteries, which take up to 1,000 years to degrade.

Real-world applications are already proving their value. In 2024, UK-based startup EnviroPower deployed sugar-powered sensors in vineyards across southern France, replacing lithium-ion batteries in soil moisture monitors. The sensors, fueled by diluted grape juice, operate continuously for six months—three times longer than disposable batteries—without needing replacement. “We used to send teams to swap batteries every two months, which added labor costs and carbon emissions from travel,” says a vineyard manager. “Now, we just top up the sugar solution once, and the old cells go straight into the compost pile.” Similarly, the city of London has trialed the fuel cells in smart waste bins: the devices use sucrose solution to power sensors that track fill levels, sending real-time alerts to garbage trucks. Early data shows this cuts unnecessary collections by 30%, reducing diesel use and urban pollution.

Beyond convenience, the technology addresses critical cost and accessibility gaps. Sugar is 80% cheaper than lithium, and far more widely available—eliminating supply chain issues that plague battery production. For remote regions, where transporting replacement batteries is logistically challenging, sugar-powered cells offer a lifeline: a single kilogram of sugar can power a temperature sensor for over a year. This has caught the attention of NGOs working in disaster zones, where low-power IoT devices (for tracking water quality or coordinating relief) often fail due to dead batteries.

Challenges remain, of course. Current models generate just 5–10 milliwatts of power—enough for sensors but not for higher-energy IoT devices like security cameras. Researchers at the University of Cambridge are addressing this by engineering more efficient enzymes, aiming to boost output by 50% by 2026. Scaling production is another hurdle: while small batches are cost-effective, mass-producing the compostable electrodes requires refining manufacturing processes to maintain consistency.

Organic compostable fuel cells represent a rare alignment of sustainability, affordability, and practicality. For those invested in green tech, urban efficiency, or global development, they offer a way to power the IoT without compromising the planet. As enzyme efficiency improves and production scales, we could soon see these sugar-fueled cells in everything from smart garden sensors to remote healthcare monitors—turning a common kitchen staple into a cornerstone of sustainable technology. In a world where “reduce, reuse, compost” is becoming more than a slogan, this innovation proves that the simplest resources can solve some of our most pressing tech-related environmental problems.

(Writer:Seli)