Hybrid Printed Electronics: Curved Surface Lighting Solutions

Curved surface lighting—found in automotive dashboards, wearable health trackers, and architectural interior panels—has long been a design and engineering challenge. Traditional lighting technologies, such as LED strips glued to curved substrates or rigid circuit boards, struggle with two critical issues: poor conformity to irregular shapes (leading to uneven brightness) and high production costs (due to manual assembly). Hybrid printed electronics, which combines the precision of inkjet printing with the scalability of screen printing, is solving these pain points, enabling seamless, energy-efficient lighting that adapts to any curved surface. This innovation is not just transforming product design; it’s opening new possibilities for how light integrates with everyday objects.

At its core, hybrid printed electronics merges two complementary printing techniques to create flexible, conductive circuits for lighting. Inkjet printing deposits tiny droplets (as small as 10 picoliters) of silver or carbon-based conductive inks onto curved substrates—such as plastic, glass, or even fabric—with microscopic precision. This allows for the creation of fine, intricate circuit patterns that power individual micro-LEDs, ensuring uniform light distribution across curved surfaces. Screen printing, by contrast, uses a mesh stencil to apply thicker layers of dielectric or adhesive inks in bulk, forming robust electrical connections and protecting circuits from wear. Together, these techniques eliminate the need for rigid components: a 2024 study by the Fraunhofer Institute showed that hybrid-printed circuits conform to curved surfaces with 98% contact efficiency, compared to just 72% for traditional glued LED strips.

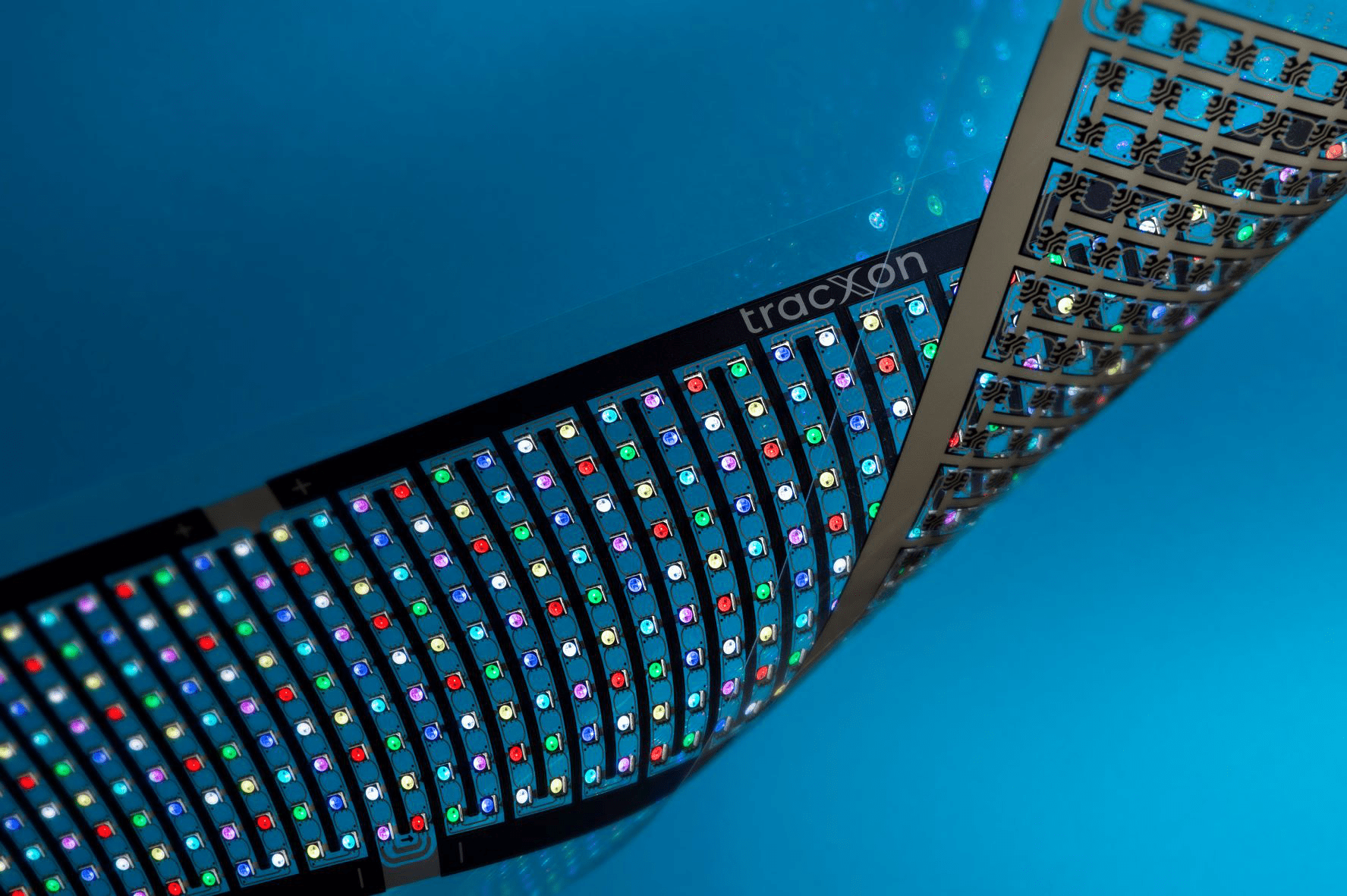

Real-world applications are already gaining traction. In 2024, German automotive supplier Continental launched a hybrid-printed curved dashboard light for BMW’s iX3 electric vehicle. The lighting system, printed onto a curved polycarbonate substrate, uses inkjet-printed silver circuits to power 120 micro-LEDs, delivering consistent brightness across the dashboard’s 15cm radius curve. Unlike previous designs, which required 14 separate components and 2 hours of assembly, the hybrid-printed version uses just 3 components and takes 10 minutes to produce—cutting production costs by 35%. For users, this translates to sleeker, more durable dashboards: the lighting system withstands 10,000 cycles of temperature changes (-40°C to 85°C) without degradation, a 50% improvement over traditional setups.

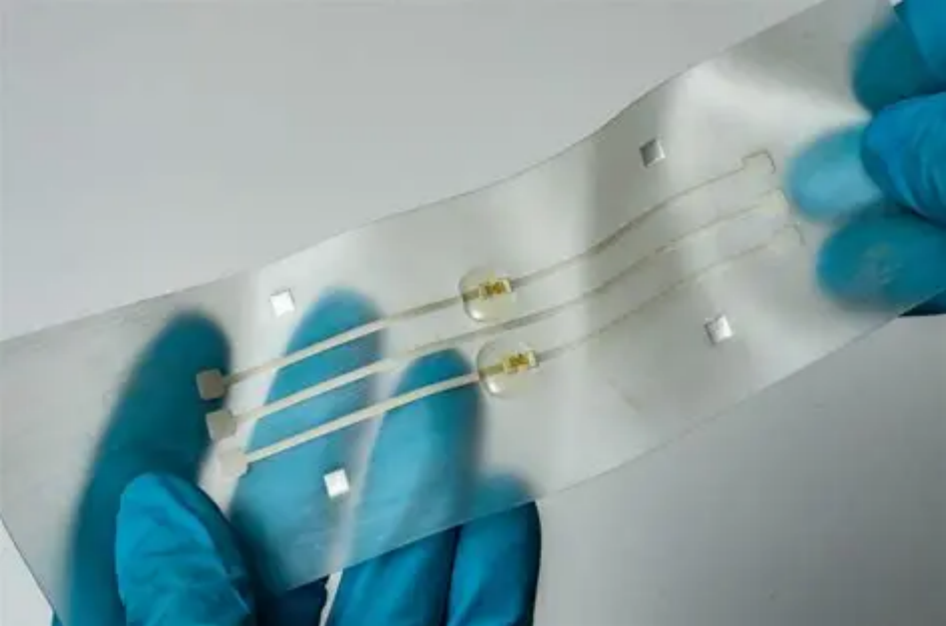

Beyond automotive, the technology is reshaping wearables. Dutch startup Lumeo recently unveiled a hybrid-printed curved lighting patch for fitness trackers. Printed onto a flexible silicone band, the patch uses screen-printed dielectric ink to insulate inkjet-printed copper circuits, powering LED indicators that glow to signal heart rate alerts. The patch bends with the wrist’s natural curve, maintaining full functionality even during intense workouts—something rigid circuit-based lights could never achieve. Early user feedback highlights its comfort: 89% of testers reported no irritation or restriction, compared to 62% for trackers with glued LED modules.

Challenges remain, however. The durability of conductive inks on highly curved surfaces is still being refined: prolonged exposure to moisture can degrade ink adhesion, though researchers at Imperial College London have developed a new hydrophobic coating that improves longevity by 40%. Scaling production for ultra-large curved surfaces—such as architectural domes—also requires faster printing speeds; current industrial inkjet printers can handle substrates up to 1 meter wide, but larger formats need specialized equipment.

Hybrid printed electronics is redefining what’s possible with curved surface lighting. By combining inkjet and screen printing, it balances precision and scalability, creating lighting that is both aesthetically pleasing and functionally reliable. For designers, engineers, and consumers alike, this technology means products that no longer force light into rigid forms—but let light adapt to the shapes that fit our lives. As ink technologies improve and production scales, hybrid printed lighting will likely become a standard feature in everything from smart home devices to medical equipment, proving that flexibility in manufacturing can unlock endless possibilities for illumination.

(Writer:Lany)